What is a Warehouse Racking System? A Beginner’s Guide

Wiki Article

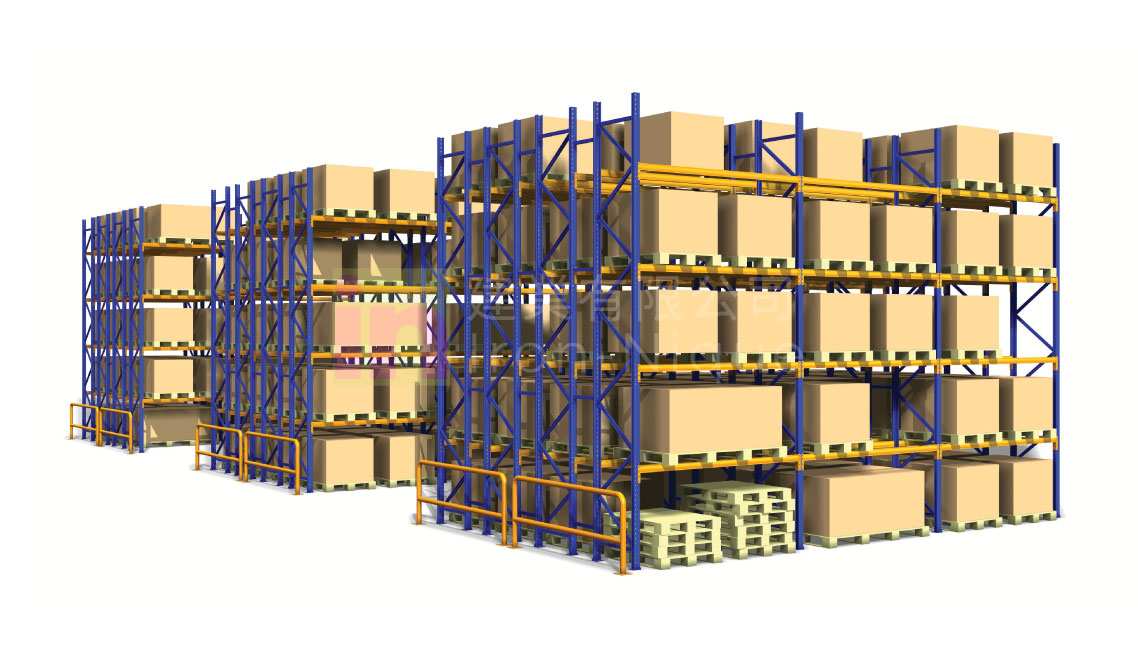

A Warehouse Racking System is the backbone of efficient storage operations. Designed to optimize space, improve workflow, and enhance safety, these systems are essential for warehouses of all sizes. This guide will explore the benefits of racking systems, their types, and how to choose the best option for your needs.

1. What is a Warehouse Racking System?

A warehouse racking system is a storage structure designed to store goods systematically using vertical and horizontal space. These systems allow businesses to organize inventory efficiently while maximizing storage capacity. Racking systems are customizable, scalable, and built to handle various types of goods, from lightweight items to heavy pallets.

2. Benefits of a Warehouse Racking System

Investing in a racking system offers multiple benefits, including:

- Space Optimization: Utilize vertical space effectively, reducing the need for additional warehouses.

- Improved Efficiency: Streamline inventory management and minimize retrieval times.

- Cost Savings: Reduce operational costs by optimizing existing storage areas.

- Safety: Ensure even load distribution and minimize workplace hazards.

3. Types of Warehouse Racking Systems

There are various types of racking systems to suit different storage needs. Let’s explore the most common ones:

3.1 Selective Pallet Racking

Selective pallet racking is the most widely used system due to its versatility and ease of access. This system allows forklifts to reach any pallet directly.

- Features: Adjustable beams, compatibility with standard forklifts.

- Best For: Warehouses with high SKU variety and frequent inventory turnover.

3.2 Drive-In Racking

Drive-in racking maximizes storage density by eliminating aisles. Forklifts can drive into the rack structure to load and retrieve pallets.

- Features: High-density storage, Last-In, First-Out (LIFO) system.

- Best For: Bulk storage of uniform products.

3.3 Cantilever Racking

Cantilever racking is designed for long and bulky items such as pipes, timber, or steel rods. Its open-front design allows for easy access.

- Features: Horizontal arms extend from vertical supports.

- Best For: Warehouses dealing with irregularly shaped items.

4. How to Choose the Right System

Selecting the best system for your business depends on several factors:

- Inventory Type: The size, weight, and variety of goods you store.

- Warehouse Layout: Analyze the available floor and vertical space.

- Storage Goals: Determine if you prioritize accessibility, density, or safety.

Explore More

To learn more about pallet racking systems, check out the Wikipedia article on pallet racking.

Why Choose Hyperack?

At Hyperack, we specialize in providing durable and efficient warehouse racking solutions tailored to your needs. Whether you need selective racking, cantilever systems, or mezzanine storage, we have the perfect solution for your business.

Follow Us on Social Media

- Facebook: https://www.facebook.com/hyperack/

- YouTube: https://www.youtube.com/channel/UCdGZlojT4q3f0j9iIqv4OnQ

- Instagram: https://www.instagram.com/hyperack/